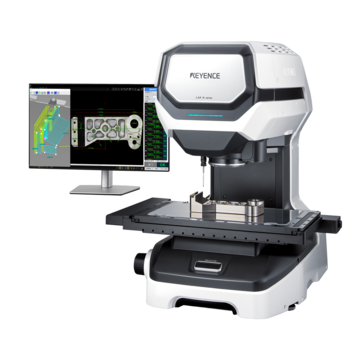

Elevate product reliability with optical measurement during final inspection stages

Elevate product reliability with optical measurement during final inspection stages

Blog Article

Why Optical Measurement Equipments Are Necessary for Modern Manufacturing Practices

In today's competitive manufacturing landscape, you can not pay for to neglect the advantages of optical measurement systems. These technologies improve precision and speed in quality control, lowering human error that can cause costly flaws. By incorporating sophisticated laser and imaging techniques, you'll improve and enhance operations product top quality. How specifically do these systems transform producing techniques, and what implications do they hold for the future?

The Advancement of Optical Measurement Solutions in Production

As modern technology rapidly advances, the advancement of optical measurement systems in manufacturing has actually changed how industries ensure accuracy and top quality. You might've discovered that standard dimension strategies, like micrometers and calipers, typically drop brief in rate and precision. Optical systems emerge as a service, leveraging light to capture in-depth dimensions promptly.

In the past, these systems were restricted, primarily used for specific applications. However now, developments in laser innovation and imaging software program permit for functional, real-time analyses throughout numerous markets. When executing these systems in your processes., you can anticipate greater precision and decreased human error. optical measurement systems.

Moreover, the integration of automated optical examination devices simplifies quality assurance, letting you focus on production efficiency. As the need for accuracy grows, adjusting to these cutting-edge optical dimension modern technologies will certainly keep your operations affordable and trustworthy in a hectic market.

Secret Benefits of Optical Dimension Technologies

Optical measurement modern technologies use several key advantages that can significantly boost your production processes. Initially, they offer high accuracy and accuracy, permitting you to make vital adjustments with self-confidence. This brings about enhanced item high quality and lowered waste, which directly affects your bottom line.

Furthermore, these systems are non-contact, meaning you can determine fragile or moving parts without causing damage. This capacity not only safeguards your products but likewise increases throughput since you can determine items on the production line without disturbance.

Optical systems are frequently quicker than traditional techniques, enabling you to collect information rapidly and make timely choices. Their convenience implies they can be related to a broad array of geometries and materials, adjusting conveniently to your specific needs. By integrating optical measurement innovations, you're not simply staying on top of industry requirements; you're setting them.

Applications of Optical Measurement in Different Industries

While many industries are significantly transforming to sophisticated dimension techniques, the applications of optical measurement systems stand apart because of their distinct abilities. In vehicle production, you'll discover these systems helping to ensure specific placement and surface area top quality in parts. In aerospace, they're important for evaluating complex geometries and guaranteeing the safety of crucial parts.

In electronics, optical measurement help in the precise positioning of integrated circuits on motherboard, improving general effectiveness. The medical device sector additionally advantages, as these systems permit for the careful measurement of elaborate components, assuring they meet stringent regulatory criteria.

Optical dimension systems are likewise used in fabrics, where they examine material patterns and flaws, improving quality. With their convenience, these systems are changing exactly how various sectors come close to dimension, ultimately driving innovation and performance in production processes.

Enhancing Quality Assurance With Optical Measurement

When it comes to top quality control, precision dimension techniques can make all the difference in your manufacturing process. By implementing optical dimension systems, you can achieve real-time top quality assurance that maintains your products reputable and consistent. This not just improves your total manufacturing effectiveness but additionally increases client satisfaction.

Accuracy Dimension Methods

In today's competitive production landscape, implementing accuracy measurement strategies can significantly boost high quality control procedures. By utilizing sophisticated optical measurement systems, you can accomplish greater accuracy and repeatability in your measurements. These strategies allow you to discover also the smallest variants in item dimensions, making sure that every part meets rigorous requirements.

Utilizing devices like laser scanners and optical comparators, you can rapidly examine the top quality of your products, considerably reducing the danger of issues. Additionally, these systems supply real-time information, allowing you to readjust processes immediately, consequently decreasing waste.

Including these precision measurement techniques not only improves product top quality but also increases customer fulfillment and self-confidence in your brand name. Accept these innovations to preserve an one-upmanship in your manufacturing operations.

Real-Time High Quality Assurance

As manufacturers undertaking for quality, real-time high quality guarantee comes to be vital for maintaining high standards. Optical dimension systems play an important role in this procedure, allowing you to monitor item top quality constantly. By integrating these systems right into your process, you can detect inconsistencies from specs almost promptly, reducing the opportunities of problems getting to the market. This prompt comments loophole enables you to make quick changes, improving manufacturing effectiveness and decreasing waste. You'll likewise cultivate a culture of top quality throughout your company, as employees can see the straight impact of their service last products. Eventually, welcoming real-time quality control with optical measurement systems not only boosts your output however additionally enhances consumer count on your brand.

Minimizing Waste and Improving Performance With Optical Systems

When you implement optical measurement systems, you'll see a significant reduction in production errors. These straight from the source systems streamline quality control processes, making it simpler to determine and fix problems rapidly. Therefore, you not only reduce waste yet also boost total performance in your production procedures.

Lessening Production Errors

To minimize manufacturing errors efficiently, manufacturers significantly depend on optical measurement systems that improve accuracy and lower waste. These systems supply real-time feedback, permitting you to determine discrepancies prior to they intensify right into costly blunders. By utilizing accurate dimensions, you can ensure that every part satisfies specifications, which substantially lowers the threat of problems. In addition, optical systems can automate numerous procedures, minimizing human error and enhancing operations. You'll find that carrying out these technologies not just boosts efficiency but likewise cultivates a culture of top quality within your group. As you embrace optical measurement systems, you'll see a marked reduction in rework and scrap prices, eventually bring about more efficient production techniques and improved bottom-line outcomes.

Streamlining High Quality Control

By taking find here on optical dimension systems, you're not just decreasing manufacturing mistakes yet additionally simplifying quality assurance. These systems provide real-time feedback, allowing you to spot problems before they escalate. As opposed to depending on hand-operated examinations, which can be taxing and vulnerable to human mistake, you can automate the process. This accelerate production and guarantees consistency throughout sets. With exact dimensions, you can recognize variations in processes or products promptly, minimizing waste and improving general efficiency. In addition, integrating optical systems assists you preserve conformity with industry standards, giving you an one-upmanship. Eventually, buying optical measurement technology boosts your top quality control, causing much better items and pleased customers.

Incorporating Optical Measurement Solutions Into Existing Procedures

Following, pick the right optical measurement innovation that straightens with your manufacturing demands. Take into consideration factors like the size of the components, required precision, and combination capacities with existing equipment. next page Educating your team on the new modern technology is essential; they need to feel confident utilizing it to maximize its benefits.

Finally, monitor the integration process very closely. Accumulate information on efficiency enhancements and identify any type of difficulties at an early stage. This positive method guarantees not just a smooth change however also a lasting effect on your production performance and product quality.

The Future of Optical Dimension in Production

As you accept optical measurement systems in your production procedures, it is necessary to look ahead and take into consideration just how these innovations will evolve. Future advancements assure improved precision and rate, enabling real-time responses that can dramatically lower production errors. You'll likely see the combination of expert system, enabling for smarter data evaluation and predictive upkeep. This means you'll not just determine yet likewise prepare for problems prior to they occur.

In addition, miniaturization of optical sensors will make them a lot more versatile, fitting right into tighter spaces and different applications. The increase of automation will certainly also improve their capacities, as automated systems will utilize these dimensions to maximize production flows effortlessly.

As you adjust to these adjustments, staying notified regarding arising modern technologies will certainly be essential. By investing in innovative optical dimension remedies, you'll position your manufacturing operations for long-term success and effectiveness. Accept the future; it's brilliant for those that innovate!

Regularly Asked Inquiries

Just How Do Optical Dimension Equipments Contrast to Traditional Measurement Methods?

Optical measurement systems offer greater rate, precision, and effectiveness contrasted to standard techniques - optical measurement system. You'll discover they decrease human error and enhance information collection, making your dimensions a lot more dependable and boosting general efficiency in your processes

What Are the Initial Expenses of Carrying Out Optical Measurement Equipments?

You'll find the preliminary prices of carrying out optical measurement systems can be significant, frequently including devices purchase, software, and training. Nevertheless, these investments commonly cause greater performance and accuracy in the long run.

Are There Certain Training Requirements for Making Use Of Optical Measurement Equipments?

Yes, you'll need details training to use optical dimension systems efficiently. Acquainting yourself with the dimension, equipment, and software application strategies is vital. Suppliers frequently offer training programs to ensure you're competent and certain in using these systems.

Can Optical Measurement Solutions Be Custom-made for Unique Manufacturing Requirements?

Yes, you can tailor optical measurement systems to meet your particular production demands. By readjusting parameters and integrating special attributes, these systems can boost precision, versatility, and effectiveness, ensuring they align perfectly with your production requirements.

What Upkeep Is Needed for Optical Dimension Equipments?

You'll require to regularly clean the optics, calibrate the system, and look for software program updates. Monitoring efficiency and resolving any kind of wear or tear without delay ensures your optical measurement systems work accurately and reliably over time.

Verdict

In today's hectic production world, embracing optical dimension systems is crucial for staying affordable. As you look to the future, investing in optical dimension will assure your operations continue to be certified and efficient, placing your business for ongoing success in the ever-evolving landscape.

As technology quickly advances, the development of optical measurement systems in manufacturing has actually transformed just how industries ensure accuracy and quality.While several industries are progressively transforming to sophisticated dimension techniques, the applications of optical measurement systems stand out due to their one-of-a-kind capabilities. By using innovative optical measurement systems, you can accomplish greater accuracy and repeatability in your measurements. Optical dimension systems play an essential role in this process, enabling you to monitor product high quality continually. Just How Do Optical Measurement Solutions Contrast to Typical Dimension Methods?

Report this page